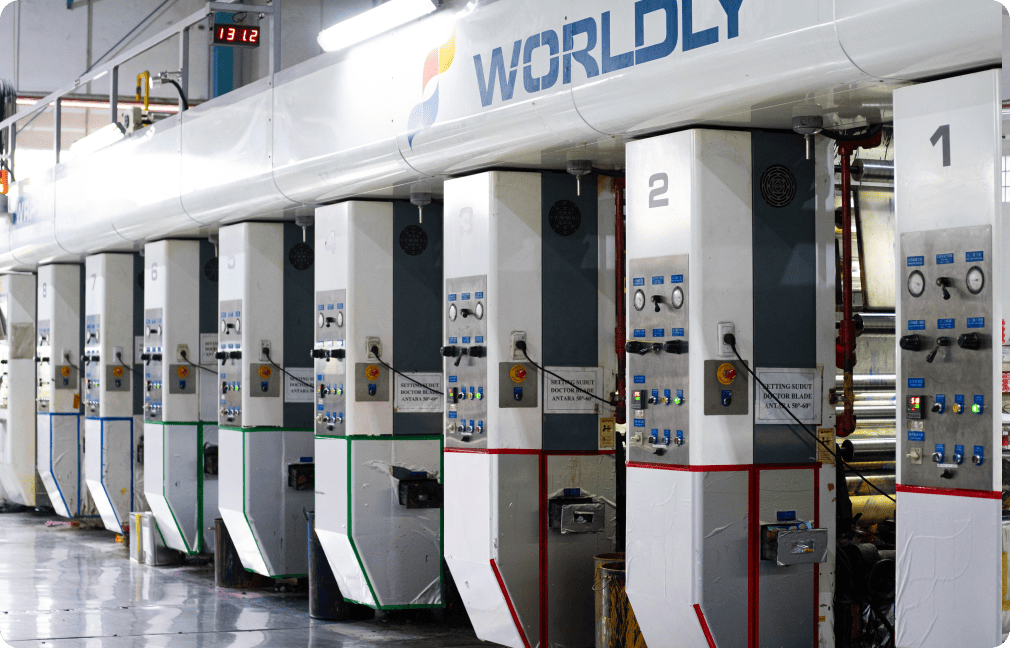

TO ANSWER THE CHALLENGES IN THE CONVERTING BUSINESS, MGI ALWAYS PRIORITIZES THE USE OF HIGH TECHNOLOGY.

MGI always prioritizes the use of the latest technology in every production process. With state-of-the-art gravure printing machines, automatic lamination systems and high-standard quality inspection equipment, we ensure every product produced meets our customers' highest expectations. Continuous innovation is our key to maintaining efficiency and quality in the flexible packaging industry.